WFI in bulk is prepared from water or from purified water by distillation in an equipment of which the parts in contact with water are of neutral glass, quarts or suited metallic & which can be fitted with an effective system to avoid the entrainment of droplets.

The concentrate regulation valve as well as movement meter are used to adjust the Restoration (which corresponds to your output).

During your inspection, establish the supply of the water used for wet granulations or for just about any aqueous liquid preparations and to the laboratory. It should be of USP purified water excellent equally chemically and microbiologically.

It can be used wherever the steam or its condensate would immediately Get in touch with official articles or posting-Speak to surfaces like throughout their planning, sterilization, or cleaning where no subsequent processing step is used to eliminate any codeposited impurity residues. These Pure Steam applications include things like but aren't restricted to porous load sterilization processes, to product or service or cleaning options heated by immediate steam injection, or in humidification of processes exactly where steam injection is used to manage the humidity inside processing vessels where the Formal content articles or their in-process kinds are exposed. The main intent of applying this quality of steam is to make certain that official article content or post-Call surfaces exposed to it usually are not contaminated by residues throughout the steam. Pure Steam is prepared from suitably pretreated resource water analogously to both the pretreatment used for Purified Water or Water for Injection. The water is vaporized with suitable mist elimination, and distributed under pressure. The sources of undesirable contaminants within just Pure Steam could crop up from entrained supply water droplets, anti-corrosion steam additives, or residues with the steam creation and distribution process by itself. The attributes in the Pure Steam monograph should detect the majority of the contaminants that might crop up from these sources. In the event the Formal posting exposed to possible Pure Steam residues is meant for parenteral use or other programs in which the pyrogenic written content should be managed, the Pure Steam must Also meet up with the specification for Bacterial Endotoxins

A validation approach for any water system ordinarily involves the subsequent techniques: (1) establishing requirements for quality characteristics from the completed water and also the supply water; (two) defining ideal device operations and their functioning parameters for accomplishing the desired finished water excellent characteristics with the offered supply water; (3) picking out piping, tools, controls, and checking technologies; (four) acquiring an IQ stage consisting of instrument calibrations, inspections to validate that the drawings precisely depict the ultimate configuration of the water procedure and, where by vital, Particular assessments to validate the installation fulfills the design demands; (5) acquiring an OQ stage consisting of tests and inspections to verify that the devices, system alerts, and controls are operating reliably Which appropriate warn and action concentrations are founded (This stage of qualification may possibly overlap with elements of the subsequent phase.

Bradley: Rising contaminants is type of the umbrella term that refers loosely to numerous types of contaminants which presence from the environment has extended been suspected, but which We've got only lately confirmed resulting from enhancements in analytical methods. The rising contaminants umbrella covers several wide lessons of contaminant compounds which are loosely categorized In accordance with their ecological impacts or their meant perform, or their resources. These can incorporate: pharmaceuticals and personal care products and solutions, natural wastewater compounds, antimicrobials, antibiotics, animal and human hormones, endocrine disrupting compounds, in addition to a a number of domestic and industrial detergents.

The financial investment may also help increase our environmental footprint with the Karlskoga web site,” clarifies Sandberg. Cambrex also a short while ago finished an up grade of wastewater managing capabilities at its Milan, Italy production facility, he reports.

Noncondensable gases in steam tend to stratify or obtain in specified areas of a steam sterilization chamber read more or its load. These surfaces would thereby be not less than partly insulated with the steam condensation phenomenon, protecting against them from enduring the full Strength on the sterilizing circumstances. For that reason, control of these kinds of steam attributes, Besides its chemical purity, could also be essential for certain Pure Steam apps. Even so, because these further attributes are use-certain, they're not talked about from the Pure Steam monograph.

Storage tanks involve venting to compensate for that dynamics of adjusting water levels. This may be completed having a appropriately oriented and warmth-traced filter housing fitted with a hydrophobic microbial retentive membrane filter affixed to an atmospheric vent. Alternatively, an automated membrane-filtered compressed gas blanketing procedure may very well be used. In equally circumstances, rupture disks equipped that has a rupture alarm unit need to be used as a further safeguard for the mechanical integrity with the tank. Regions of problem involve microbial growth or corrosion on account of irregular or incomplete sanitization and microbial contamination from unalarmed rupture disk failures caused by condensate-occluded vent filters.

Microbial-Retentive Filtration Microbial-retentive membrane filters have expert an evolution of being familiar with in past times 10 years which has caused previously held theoretical retention mechanisms being reconsidered. These filters more info have a larger efficient “pore measurement” than ultrafilters and are meant to protect against the passage of microorganisms and in the same way sized particles devoid of unduly restricting stream. This type of filtration is extensively used in water programs for filtering the microorganisms outside of the two water and compressed gases in addition to for vent filters on tanks and stills together with other device functions. Having said that, the Houses of your water program microorganisms appear to obstacle a filter's microbial retention from water with phenomena absent from other aseptic filtration applications, including filter sterilizing of pharmaceutical formulations just before packaging. While in the latter software, sterilizing grade filters are typically considered to have an assigned score of 0.

A specification excursion may induce an intensive concluded solution impression investigation, sizeable remedial steps inside the water program that could contain a complete shutdown, And maybe even product or service rejection.

Diluting medicinal goods: The purification level of this kind of pharmaceutical water causes it to be a sterile diluent for parenteral medication.

The smoothness and composition from the surface may perhaps impact the rate of initial microbial adsorption, but when adsorbed, biofilm progress, Except usually inhibited by sanitizing disorders, will occur whatever the surface. The moment formed, the biofilm gets to be a steady source of microbial contamination.

It contains multi–quality sand particles that are layered intimately in particular proportions. This makes certain just one obtains both of those surface and depth filtration.

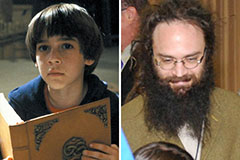

Barret Oliver Then & Now!

Barret Oliver Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Batista Then & Now!

Batista Then & Now!